A wedding cross is a meaningful addition to a wedding ceremony, and building one can be a fun and rewarding project. The process involves selecting the right type of wood, cutting and joining the pieces, and finishing the cross to achieve the desired look. While it may seem daunting at first, it can be a suitable project for both beginners and advanced woodworkers. In this article, we will provide a step-by-step guide on how to build a sturdy and aesthetically pleasing base for a wedding cross.

| Characteristics | Values |

|---|---|

| Height | 8-15 feet |

| Width | 5-6 feet |

| Base | 2x4 (8ft long), cut in half |

| Base diameter | 3 feet |

| Wood type | Cedar, pine, cypress, redwood, oak |

| Joint type | Half-lap joint |

| Bolts | 5-inch lag bolts |

What You'll Learn

Choosing the right wood

When choosing the right wood for your wedding cross, there are a few things to consider. Firstly, the type of wood you choose will depend on the desired colour and finish. For example, if you want a rich, dark colour, Western Red Cedar is a good option, as it is lightweight, strong, and resistant to decay. It is also easy to work with and can be ordered from local home improvement stores. Alternatively, pine is another suitable wood for wedding crosses, though it may require staining to achieve a darker colour. If you are looking for a more affordable option, pressure-treated pine is a good choice, but keep in mind that it may not last as long as other types of wood.

Another important consideration is the size and thickness of the wood. If you want a tall and substantial-looking cross, you will need to choose thicker wood, such as 6x6 or 8x8 beams. However, keep in mind that thicker wood will also make the cross heavier. If you are concerned about weight, you may want to consider using a thinner wood, such as 4x4, or even 2x4 if you are looking for something more lightweight.

When selecting wood for your wedding cross, it is also essential to think about the workability of the material. Some types of wood are easier to cut, sand, and shape than others. If you are a beginner, it is advisable to choose a wood that is soft and easy to work with. Additionally, consider the availability of the wood and your budget. Some types of wood may be more expensive or difficult to source, so it is important to plan accordingly.

Finally, if your cross will be displayed outdoors, you will need to choose a type of wood that is durable and weather-resistant. Cedar and Redwood are good options, as they have natural pest and rot resistance. Treated pine is another option for outdoor projects, but it may not last as long as other types of wood.

Creative DIY Gift Boxes for Wedding Favors

You may want to see also

Getting the right dimensions

Height and Width:

- The height and width of your cross should be proportional to the size of the wedding venue and the desired visual impact. A taller and wider cross will be more visible to the wedding guests, especially if the ceremony is held in a large space.

- A common rule of thumb is to build the cross such that its overall height in feet is equal to the width of the wood planks in inches. For example, if you're using 5-inch-wide planks, construct a cross that is 5 feet tall.

- For a church interior, a cross that is 12 feet high and 6 feet wide is generally considered appropriate.

Base Size:

- The stability of the cross is heavily dependent on the size of its base. A wider base will provide more stability, especially if the wedding is held outdoors, where it may be exposed to wind or other elements.

- For a 10-foot-tall cross, a base diameter of 3 feet can provide sufficient stability. If you're concerned about stability, consider using sandbags or anchoring the base to the ground or floor.

- If the cross is to be mounted outdoors, the vertical beam will need to be longer to allow for sinking it into the ground for stability.

Cross Section:

The cross section, which forms the shape of the cross, should be proportional to the base. A common approach is to use a prism shape, where the height of the prism equals one of the cross-sectional dimensions, creating a balanced appearance.

Wood Type:

- The type of wood you choose will impact the overall dimensions of the cross due to differences in wood strength and weight. Softer woods like pine tend to be lighter but may not be as strong or durable as harder woods.

- Consider the weight of the wood, especially if you'll need to transport or move the cross. Western Red Cedar, for instance, is lightweight yet strong and resistant to decay, making it a good choice.

- If you're looking for a rustic or outdoor wedding cross, cedar or pine are suitable options. For a richer colour, you can stain the wood or choose a wood with a natural colour that aligns with your desired aesthetic.

Latin Cross vs. Greek Cross:

- The Latin cross has unequal arms, with the top projection (vertical beam) typically longer than the horizontal beam. The goal is to have the three top projections of equal length.

- The Greek cross, on the other hand, has equal arms, creating a symmetrical shape.

Personalisation:

Consider the overall aesthetic you wish to achieve. Do you want a contemporary cross or a rustic one? Do you plan to add any carvings or adornments? These design choices will influence the dimensions and proportions of your cross.

Creating a Memorable Wedding Toss Bouquet

You may want to see also

Cutting notches for joints

Marking the Notches:

Begin by carefully marking the locations of the notches on both the vertical and horizontal beams. Place one beam on top of the other at the point where they will intersect, and use a pencil to mark the notch outlines. The notches should be deep enough to create a secure joint, typically around 2 inches deep.

Adjusting the Blade Depth:

Before cutting, adjust the blade depth on your handheld circular saw to match the desired notch depth. In this case, set the blade depth to 2 inches. This ensures that your cuts will be consistent and at the correct depth.

Making a Series of Cuts:

Using the circular saw, make a series of cuts across the wood within the marked notch area. These cuts should be parallel to each other and spaced closely together. The goal is to remove most of the wood within the notch while maintaining control and precision.

Chisel Out the Notch:

After making the cuts, use a chisel to remove the remaining wood within the notch. Chisel carefully along the cut lines, cleaning up the notch and creating a smooth, flat surface. This step ensures that the notches are precise and fit together snugly.

Test the Fit:

Before proceeding, it's a good idea to test the fit of the notches. Place the beams together at the notches and ensure that they mate correctly. If adjustments are needed, use the chisel to make minor corrections to the notch dimensions. A snug fit is ideal, as this will create a strong joint.

Fine-Tuning:

If necessary, make any final adjustments to the notches. This may involve additional cutting or chiselling to achieve the perfect fit. It's important to take your time during this step to ensure that the notches are as precise as possible.

By following these steps, you will be able to cut notches for joints effectively, creating a strong and secure joint for your wooden wedding cross. Remember to work carefully and take measurements twice to ensure accuracy. With precise notches, your cross will have a solid foundation, and you'll be one step closer to completing your meaningful project.

Creating a Wedding Gown Train: Secrets to a Stunning Train

You may want to see also

Drilling holes for bolts

Tools and Materials:

Before you begin, gather the necessary tools and materials:

- Power drill: A corded drill is recommended for this project. Ensure it's in good working condition and has enough power to drill through the wood.

- Drill bits: Use a 1/2-inch drill bit for the bolt holes. You may also need smaller drill bits for pilot holes and countersinking.

- Lag bolts: Two 5-inch lag bolts are typically adequate to connect the beams. Choose bolts with a diameter that matches the drill bit size.

- Wrench: You will need a wrench to tighten the nuts on the lag bolts.

- Safety gear: Wear safety goggles and gloves to protect your eyes and hands during drilling.

- Wood beams: Ensure you have the vertical and horizontal beams for the cross ready.

Step-by-Step Guide:

- Mark the Drill Points: Carefully mark the points where you will drill the holes. The holes should be aligned so that the bolts can pass through both beams and secure them together.

- Drill Pilot Holes (Optional): If desired, you can start by drilling smaller pilot holes to guide your drilling and prevent the wood from splitting. Drill these holes with a smaller drill bit at the marked points.

- Drill the Main Holes: Using the power drill and the appropriate drill bit, drill the main holes at the marked points. Ensure the holes are straight and deep enough to accommodate the lag bolts. You may need to adjust the drill depth or use a chisel to ream out the holes slightly if the bolts don't fit snugly.

- Countersink (Optional): If you want the bolt heads to sit flush with or below the wood surface, use a countersink bit or the reverse function on your drill to create a countersink for the bolt heads.

- Insert the Lag Bolts: Insert the lag bolts into the drilled holes. The bolt heads should be on the front face of the cross, providing a neat appearance.

- Tighten the Bolts: Use a wrench to tighten the nuts on the lag bolts securely. Ensure the beams are firmly connected and the joint feels stable.

- Test the Connection: Once the bolts are tightened, test the strength of the connection by gently trying to move the beams relative to each other. Ensure there is no wobbling or looseness.

- Disassembly (Optional): If you plan to transport or store the cross, you may want to disassemble it. Loosen the nuts with the wrench and separate the beams. Mark the beams to ensure proper alignment during future assembly.

Drilling accurate and straight holes is crucial for the stability and aesthetics of your wedding cross. Take your time, use the correct drill bits, and ensure a secure connection with the lag bolts. Always follow safety precautions when operating power tools, and wear the appropriate safety gear.

Creating Beautiful Indian Wedding Garlands: A Step-by-Step Guide

You may want to see also

Finishing touches

Now that the base is built, you can add some finishing touches to it. If you want to add some colour to the base, you can apply a finish. You can use a natural oil finish with tung or linseed oil, mineral spirits, and polyurethane. Alternatively, you can use an outdoor finish like polyurethane, epoxy, lacquer, or varnish. You can also use a stain-sealant combo to add colour and finish in one.

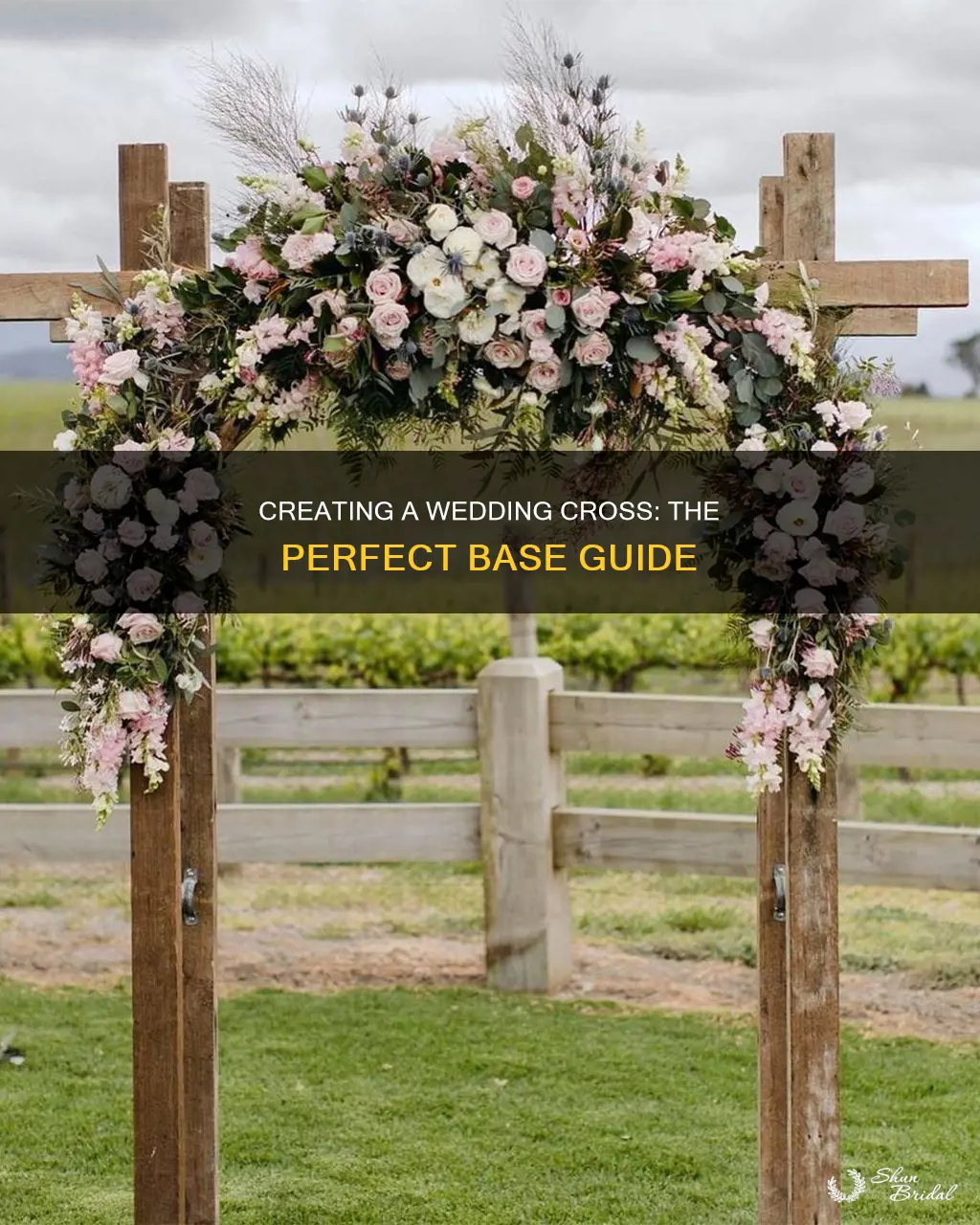

If you want to add some extra stability to the base, you can anchor it down or add sandbags to weigh it down. This is especially important if the wedding is outdoors, as you don't want the cross to be blown over by the wind. You should also ensure that the room has adequate height for the cross and coordinate with decorators if they want to add flowers or foliage.

Finally, make sure to set up the cross the day before the ceremony and get someone to help you lift and stabilise it. You don't want it to be unstable and fall over during the wedding!

Creating Wedding Garland: Fresh, Fragrant, and Festive Decor

You may want to see also

Frequently asked questions

The most typical dimension for a cross is a 1:3 ratio. The cross arm is attached 1/4 of the way down from the top of the cross and has a width that is a third of the height of the cross.

The Christian cross is viewed as a representation of Jesus being crucified on a large wooden cross. It is a renowned symbol of Christianity.

For a wedding cross, you can use any type of wood. Tropical hardwoods are a good option as they last the longest and come in a variety of colours and grains. However, they are more expensive than other types of wood.

Although there is no hard and fast rule, the overall height of the cross should be equal to the width of the wood planks in inches. For example, 5-inch-wide planks should be used to build a 5-foot-tall cross.

You can use a finish that is suitable for outdoor use, such as polyurethane, epoxy, lacquer, or varnish. Alternatively, you can create a natural oil finish by mixing one part tung or linseed oil, one part mineral spirits, and one part polyurethane.