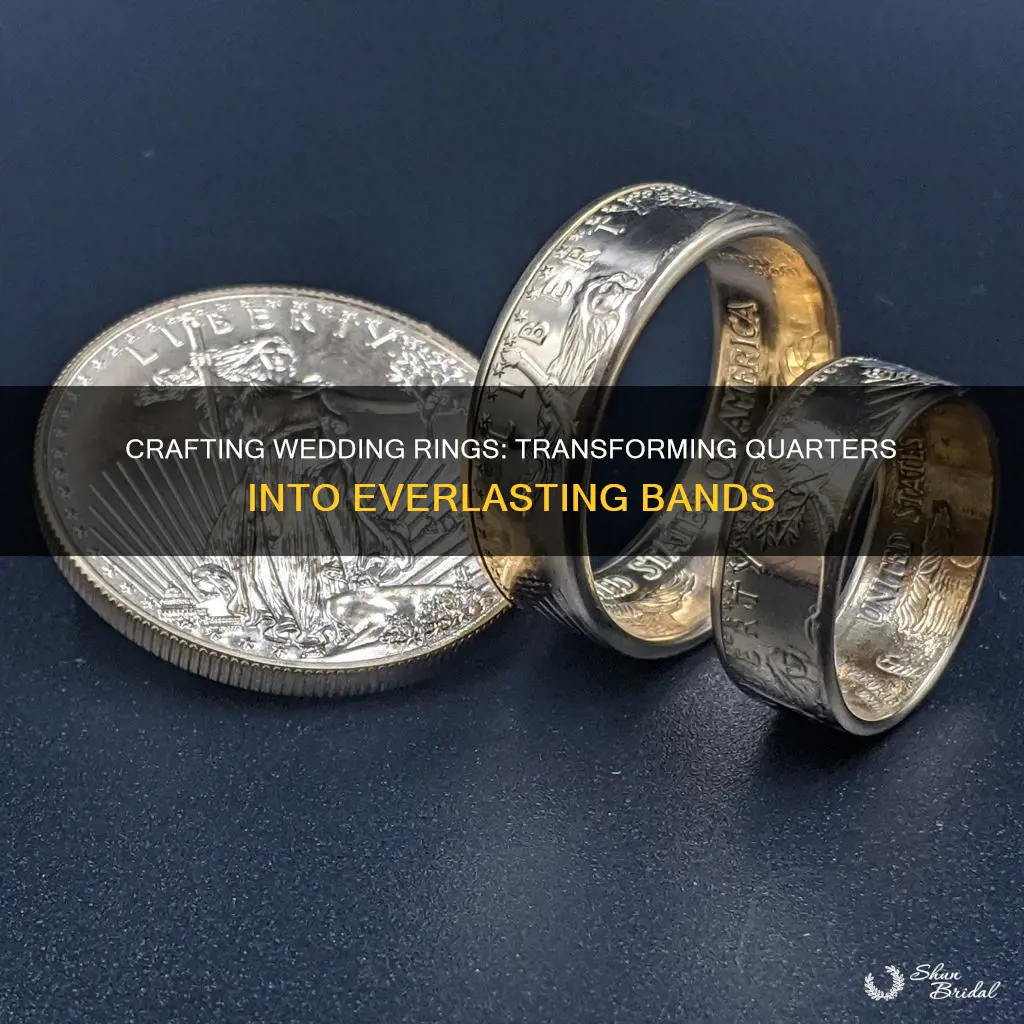

Making a wedding ring out of a quarter is a fun, if time-consuming, project. It requires a quarter made of silver, which in the US means a quarter from 1964 or earlier. You'll also need a heavy stainless steel soup spoon, a knife with a small sharp blade, 2000-grit sandpaper, and an anvil or another flat piece of heavy metal.

The process is simple, but it takes time and patience. First, you tap the edge of the coin with the spoon, turning it slowly as you go, until the coin is the width of your finger. Then, you drill a hole in the centre of the coin and smooth the inside with sandpaper. Finally, you sand and polish the ring until it shines.

| Characteristics | Values |

|---|---|

| Tools | Heavy stainless steel soup spoon, knife with a small sharp blade, sheet of 2000 grit sandpaper, anvil (or any flat heavy piece of steel), power drill, Dremel tool, hammer |

| Materials | Silver quarter dated before 1964 |

| Time | 5 minutes a day for a month |

What You'll Learn

Choosing the right coin

The size of the coin will determine the thickness of the ring, so it is important to choose a coin that is the right size for the finger of the person who will be wearing it. A quarter is a great size for most people, but for someone with larger fingers, a half-dollar may be a better choice. It is also important to choose a coin that is not too worn, as the date and design on the coin will be visible on the inside of the ring.

Once you have chosen the right coin, you can begin the process of making the ring. This involves tapping the coin with a hammer or spoon to widen the edge, drilling a hole in the centre, filing and sanding the inside of the ring, and finally polishing the ring to give it a smooth, shiny finish.

Creating Wedding Cake Flower Decorations: A Step-by-Step Guide

You may want to see also

Tools you'll need

Making a wedding ring out of a quarter requires a few tools. Here is a list of the tools you will need:

- A quarter: It is important to use a quarter that is made of silver. Quarters issued before 1964 in the United States are 90% silver, while those issued after 1965 are made of copper and nickel.

- A heavy stainless steel spoon: The weight and shape of a soup spoon ensure that only a small portion of it strikes the coin, reducing the chance of a glancing blow.

- A knife with a small sharp blade: This will be used to make a hole in the centre of the coin.

- Sandpaper: 2000-grit sandpaper can be used to smooth the edges of the ring and the inside of the band.

- An anvil or any flat, heavy piece of steel: This will serve as a sturdy surface on which to work.

- A drill: A very accurate drill or a laser-guided drill press can be used to make the hole in the centre of the coin.

- A Dremel tool: This can be used to widen the hole and smooth the inside of the ring.

- Polishing cloth and silver polish: These will be used to polish the ring and give it a shiny finish.

Crafting Delicate Wedding Bouquet Picks: A Step-by-Step Guide

You may want to see also

Flattening the coin

Firstly, select a suitable coin. Quarters are a popular choice due to their larger size. It is recommended to use quarters made before 1965 as they contain 90% silver. Alternatively, you can opt for half-dollar coins, which are also larger in size.

Now, gather the necessary tools and materials. You will need a vise, a ring-sizing mandrel, a drill and drill bit, a handheld rotary tool, a carbide cutting bit, calipers, sandpaper, a felt polishing tip, and polishing compound. Additionally, ensure you have access to a garage or workshop space to accommodate all the tools.

To begin the flattening process, set the coin in the vise. You can either secure the coin in the grip of the vise or hold it between your index finger and thumb to keep it in a standing position. Lightly tap the edges of the coin with a hammer, rotating it slightly with each tap to ensure even flattening. This process can take up to two hours, so be prepared for a lengthy task.

As you tap, periodically check for warping by laying the coin flat on the vise and inspecting for any spaces between the coin and the surface. Correct minor warping with light tapping or sanding later in the process.

Once the edges are completely flattened and widened, use calipers to measure the inside diameter of the coin to determine the desired ring size. If you want a half-round band, lean the coin at a 75-degree angle and lightly tap the edges toward the center, rotating as you tap.

Before proceeding further, smooth the outer edges of the coin with 200-220 grit sandpaper to remove any waviness or warping. Be careful not to remove too much material, as you want to preserve the text and features of the coin.

Now, it's time to drill a hole in the center of the coin. Secure the coin inside the vise grip with a towel or rag to protect the edges. Use a compatible drill bit size with your carbide cutting bit, such as 1/8" or 3/16". Push the drill bit through the coin, being careful not to push too hard and cause the coin to slip.

Finally, cut out the middle of the coin with the rotary tool and carbide cutting bit. Run the rotary tool at a high speed for a smooth and clean cut. Be extremely cautious during this step to avoid damaging the inside of the ring and losing the unique coin face and text.

In conclusion, flattening a coin to create a wedding ring is a meticulous and time-intensive process. By following these steps and exercising patience, you can successfully transform a quarter into a unique and meaningful wedding ring.

Crafting Yarn Wedding Baskets for an Indian Wedding

You may want to see also

Drilling the hole

To start the hole, hold the coin against the index and middle finger of your right hand. Then, take a small, sharp knife and hold it in your left hand with your thumb and index finger on the blade, about half an inch back from the point. With the coin steady, put the point of the knife into George Washington's ear and begin to turn the knife back and forth to start the hole. This is a slow process, so take your time.

Once the hole is drilled through to the other side, turn the coin over and work from that side. When the blade comes through and you can feel it with your finger, stop and reposition the coin. Stand the coin on its edge on the table and hold it steady with your thumb and forefinger, pressing it down firmly. Now, you can continue to cut away at the inside of the hole, and as it gets bigger, the work will become easier.

Once the hole is big enough to fit your finger through, the ring is almost complete. The final step is to use sandpaper to smooth the inside of the ring, being careful not to remove any of the date or lettering.

Creating a Wedding Photo Frame Prop: A Step-by-Step Guide

You may want to see also

Smoothing and polishing

Step 1: Prepare the Ring's Surface

Before you begin polishing, it's important to prepare the surface of your ring thoroughly. Ensure that any deep marks, scratches, or fire stains are addressed, as these issues may become more apparent during the polishing process. Take your time with this step, as it will save you valuable effort later on.

Step 2: Choose Your Tools

Polishing can be done by hand or with power tools. Hand polishing offers more control, precision, and convenience, while power tools can speed up the process. You can also use a combination of both methods. For hand polishing, you'll need polishing papers or cloths, and for power tools, you can use a rotary tool like a Dremel with various attachments.

Step 3: Sanding

Sanding is an important step to smooth out the surface of your ring and eliminate any marks or scratches. Use graded wet and dry sanding sheets, starting with a coarse grade and working your way up to a finer grade. You can also use sanding and polishing sticks, which have the sanding paper secured to a flat piece of wood. Work your way around the entire ring, ensuring that you change the direction of your sanding motion between grades to avoid flattened areas and achieve an even finish.

Step 4: Inspect Your Work

After sanding, take a critical look at your ring under magnification to ensure there are no remaining deep marks or scratches. Any obvious marks left at this stage are likely to become more apparent after polishing, so it's important to address them now. With practice, you'll develop an eye for what your ring should look like at this stage.

Step 5: Polishing

Now it's time to polish your ring. If using a power tool, attach a polishing mop or wheel to your rotary tool. Apply a small amount of polishing compound, such as tripoli or rouge, to the mop or wheel and gently work it all over the ring. Remember to keep the mop or wheel moving to change the direction of the polish. If hand polishing, you can apply the polishing compound to a piece of leather, suede, or string and rub it vigorously onto the ring, changing directions often.

Step 6: Final Touches

Once you've achieved your desired level of shine, use a jewellery polishing cloth to give the ring a final buff and remove any fingerprints or greasy marks. Your wedding ring is now ready to be worn and admired!

Create Paper Pom-Poms for a Wedding: Easy DIY Guide

You may want to see also

Frequently asked questions

You should use a silver coin, such as a quarter made in the US before 1964, as these are 90% silver.

You will need a heavy stainless steel soup spoon, a knife with a small sharp blade, a sheet of 2000-grit sandpaper, and an anvil (or any flat, heavy piece of steel).

Place the quarter on the anvil and hold it firmly between your thumb and index finger. Tap the rim of the quarter with the outside of the spoon, turning the coin slowly as you tap. Continue this process until the rim is wide enough to be a ring. Next, drill a hole in the centre of the coin and use a knife to cut away the silver inside the ring until it is the correct size for your finger. Finally, sand the inside and outside of the ring to smooth it out.