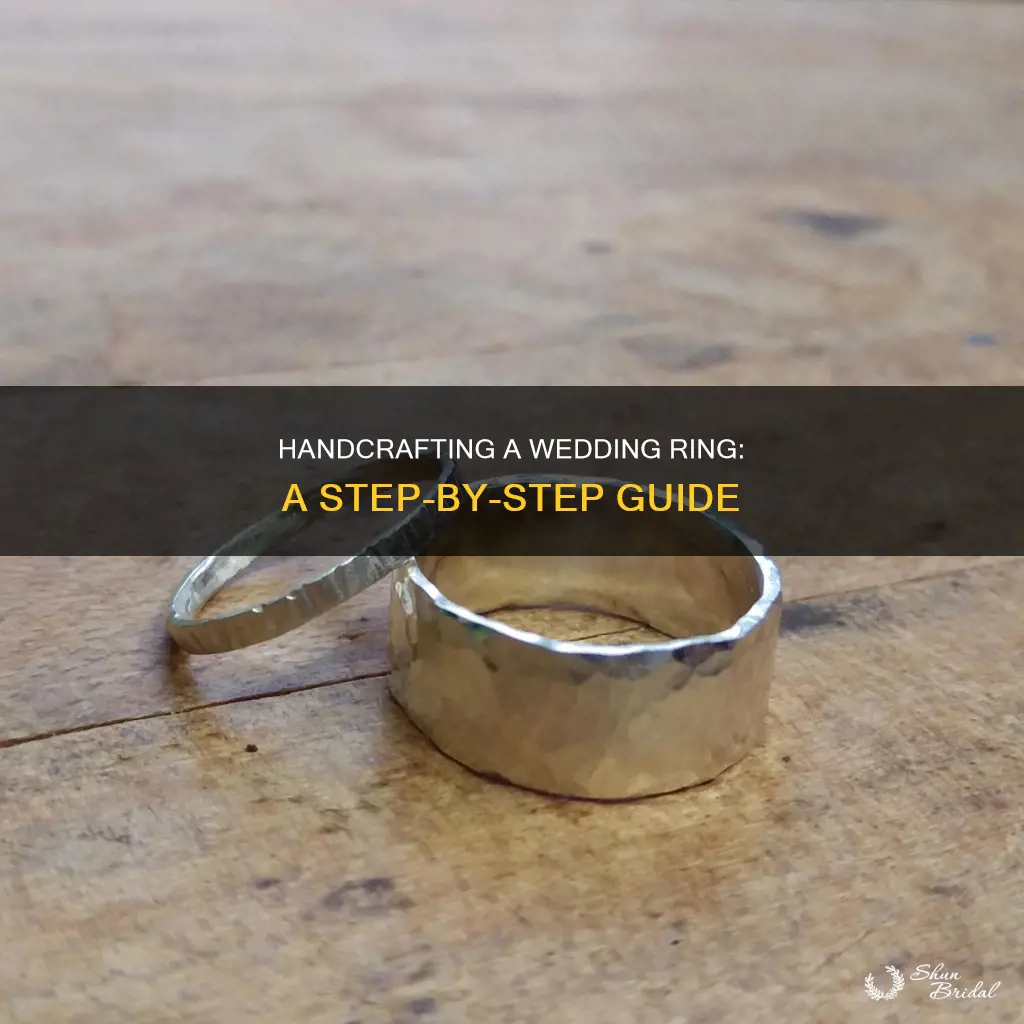

Making a wedding ring from scratch is no easy feat. It requires a great deal of skill, experience, and precision. The process involves selecting the right materials, designing the ring, and carefully crafting it. While it may seem daunting, creating a custom wedding ring allows you to design a ring that is truly unique and reflective of your taste and style. Whether you choose to work with a professional jeweller or attempt it yourself, making a wedding ring from scratch is a complex and rewarding endeavour.

| Characteristics | Values |

|---|---|

| Materials | Platinum, Gold, Diamond, Resin |

| Tools | Hand-cranked extruder, Mandrel, Blowtorch, Emery paper, Cotton mop |

| Techniques | Lost wax casting, Machining, 3D printing, Casting, Brazing |

| Steps | Select centre stone, Design ring, Cut and shape metal, Braze, Sand, Polish, Set stone |

What You'll Learn

Selecting the right stone

Durability is an important consideration, as wedding rings are meant to be worn daily and endure a lot of wear and tear. The Mohs Hardness Scale, which ranks gemstones on a scale from 1 to 10, can be a helpful guide. Stones that rank higher on the scale, like diamonds (10) and sapphires (9), are more resistant to scratches and chips. Aim for a stone that is at least a 7.5 or higher on the scale to ensure longevity.

Colour also plays a significant role in stone selection. Some people prefer neutral colours that coordinate effortlessly with any wardrobe choice, while others seek bright and eye-catching colours that stand out. Colour psychology can be a fun way to choose a stone that represents specific messages or themes, such as red for love and passion or green for growth.

Additionally, the cut and size of the stone are important factors. The natural angles and features of a diamond can make it appear more brilliant than its grade suggests, so examining the stone in person is advisable. The size of the stone can also impact the overall design and setting of the ring, with larger stones often requiring a more secure setting.

When selecting a stone, it is essential to consider your budget. While diamonds are highly valued, other gemstones can offer a more affordable alternative without compromising on beauty. For example, gemstones like sapphires, rubies, and emeralds are known for their rich colours and durability, making them a popular choice for engagement and wedding rings.

Ultimately, the choice of stone should be a personal one that reflects your personality and style. Whether it's a diamond, a colourful gemstone, or a unique alternative, selecting the right stone will ensure that your wedding ring is not only aesthetically pleasing but also durable enough to last a lifetime.

Crafting Large Paper Flowers for Wedding Decorations

You may want to see also

Designing the ring

The first step in designing a wedding ring is to select the centre stone. Diamonds are graded based on their cut, colour, and clarity, but it's important to see the stone in person to assess its natural angles and features, which can give it a sparkle that outshines its grade. The carat of the diamond is also a key consideration, but it's important to remember that size isn't everything. The most beautiful stone for your budget might be smaller but more brilliant.

Next, you'll want to create a design for your ring. This is where you decide on the setting that will show off your chosen stone to the best effect. You can use hand sketches and Computer-Aided Design (CAD) to visualise the ring from different angles and ensure every detail is right before moving on to the next stage.

After finalising the design, create a 3D-printed model of the ring, which can be tried on with the stones in place. This step allows you to make any necessary adjustments before moving forward with the final materials.

Once you're happy with the design, it's time to select the metal for the band. Popular choices include gold and platinum, but you can also choose alternative metals like rose gold or white gold.

At this stage, you can also decide on any additional details you want to include, such as engraving.

Finally, work with your jeweller to finalise the design, ensuring that it meets your specifications while maintaining durability.

Crafting Wedding Pocket Squares: A Step-by-Step Guide

You may want to see also

Sourcing materials

The first step in making a wedding ring is to source the materials. This includes the metal for the band, any gemstones or diamonds, and any other necessary tools or equipment.

For the band, popular metal choices include gold, platinum, silver, or rose gold. These metals can be purchased from jewellery suppliers or online retailers. It is important to consider the colour, durability, and price of the metal when making your selection.

If you plan to include any gemstones or diamonds in the ring, these will also need to be sourced. Diamonds are graded on characteristics like cut, colour, and clarity, and it is important to select a stone that fits your budget and design preferences. Gemstones can add a unique pop of colour to the ring, with popular choices including sapphires, emeralds, and rubies.

In addition to the band and stones, you will need to source the necessary tools and equipment for working with the materials. This may include items such as a hand-cranked extruder, mandrel, solder, blowtorch, and various sanding and polishing tools.

When sourcing materials, it is important to consider your budget and the complexity of your ring design. Custom engagement rings with larger diamonds or more intricate designs will typically cost more, while simpler designs with engraving or smaller stones may be more affordable.

It is also worth considering the time it will take to source the materials, especially with pandemic-related supply chain disruptions. Giving yourself plenty of time to source high-quality materials will ensure a smooth process and a beautiful final product.

Creating Personalized Wedding Candles: A Step-by-Step Guide

You may want to see also

Soldering and hammering

Soldering is the process of connecting two metal pieces using a metal alloy, or solder, that melts at a very low temperature. In the context of wedding rings, soldering is often done to join the wedding band and engagement ring together so they can be worn as one. This process is relatively affordable, typically costing around $45. While soldering is a great option for those who want to wear their wedding band and engagement ring together, it is important to consider that soldering makes it difficult to wear the rings separately. Additionally, certain metals such as titanium and tungsten cannot be soldered.

When soldering wedding rings, it is essential to ensure that both rings have flat sides so that the details of the rings are not distorted. Additionally, the rings should be sized up before soldering, as soldered rings tend to fit tighter.

After soldering, the ring is hammered into shape. A steel spike called a mandrel is used to achieve a precise round shape and the correct finger size. Hammering also hardens the metal, making the ring more durable. Once the ring has been hammered into shape, it is important to remove any excess metal and ensure that the joins are seamless and free of visible hammer marks.

Crafting Indian Wedding Baskets: Traditions and Techniques

You may want to see also

Polishing

There are several techniques you can use to polish your ring, depending on the type of ring you have.

Warm Water and Soap

This method works for most rings. Fill a bowl with warm water and add a few drops of basic dishwashing soap. Remember to avoid harsh cleaning liquids as this can damage your ring. Soak your ring in the bowl for about 20-30 minutes. Gently brush your ring with a soft toothbrush to remove any residue, especially in any grooves in the ring's design and setting. Rinse your ring off in warm water to remove any remaining soap and pat it dry with a soft cloth.

Baking Soda and Vinegar

Mix 1/2 cup (120 mL) of vinegar and 2 tbsp (28.3 g) of baking soda in a small plastic container. You will start to see a bubbling reaction. Submerge your rings in the solution for 2-3 hours, ensuring the rings are completely submerged the entire time. Check the rings every 30 minutes. Remove the rings from the solution and scrub them with a toothbrush, paying special attention to particularly tarnished areas. Rinse the rings under cold water to remove any residue and dry them with a soft, clean cloth.

Beer

Pour a fresh beer into a glass or bowl. Place your rings into the glass or bowl and let them soak for 10-15 minutes. Rinse your rings with warm water and dry them with a soft cloth.

Lemon Juice and Salt

Add 1.5 cups (350 mL) of warm water to a bowl and stir in 1 tbsp (17 g) of salt and 1 US tbsp (15 mL) of lemon juice. You can also add 0.5 cups (34 grams) of dry milk to the mixture. Place your rings in the solution and soak for 6-8 hours. Remove your rings and rinse them in warm water, then dry them with a soft cloth.

Aluminium Foil and Baking Soda

Place aluminium foil along the bottom and sides of a bowl. Fill a pot with water and bring it to a boil. Add 1 tbsp (14.3 g) of baking soda per 1 cup (240 mL) of water and stir the mixture for about 5 minutes. Put the rings in the bowl so that they are touching the aluminium foil and let them sit for 5 minutes. Pour the solution into the bowl and let the rings sit for 10 minutes. Remove the rings and allow them to dry on a towel for 15 minutes, then finish drying them with a clean, white cloth.

Silver Polish

Squeeze a small amount of silver polish onto a clean cloth. Rub the polish onto your rings in an up-and-down motion, not a circular motion, as this will highlight any scratches. Rinse the rings and dry them with a cloth.

Toothpaste

Apply non-gel toothpaste directly to your ring and use a wet toothbrush to scrub it gently. Rinse the ring with cold water and dry it with a cloth.

Ring Polishing Kits

If you don't want to attempt to polish your ring yourself, you can buy a ring polishing kit. These kits include everything you need to polish your ring at home, such as polishing cloths, cleaning brushes, and polishing compounds.

Afternoon Wedding Reception: Ensuring Fun and Energy

You may want to see also

Frequently asked questions

The first step is to select the centre stone.

The next step is to create a design for the ring. You can use hand sketches and Computer-Aided Design (CAD) to visualise the ring from different angles.

Once the design is ready, use a 3D printer to create a resin model of the ring. You can then try it on and make any necessary adjustments.

The 3D model is sent to a casting company that creates moulds of the ring and casts them in precious metal. The rough pieces are then refined and crafted into the final product.

The final step is to polish the ring to give it a glittering shine.