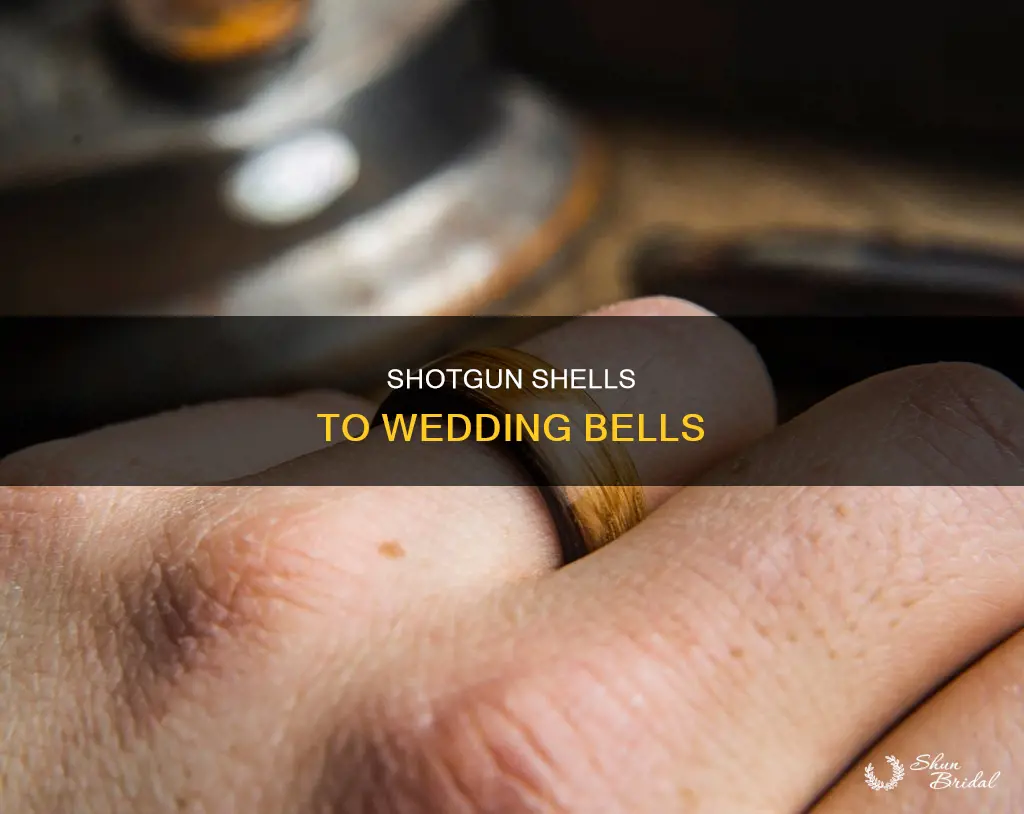

Shotgun barrel wedding bands are rings made from decommissioned shotgun barrels. They are marketed towards men who want a wedding band that is as rugged as [they] are. The barrel bands are handcrafted in the USA and made from stainless steel shotgun barrels. The process of making these rings involves machine-cutting the barrel to the right size, adding a 14-karat gold insert, and then polishing the ring. The company that makes these rings, Everyday Outdoors, emphasizes the connection between the shotgun and the outdoor world, as well as the reliability of the shotgun in different terrains and climates.

What You'll Learn

Shotgun barrel wedding bands are made from decommissioned guns

Deactivated guns are popular among collectors and enthusiasts, offering a way to own a piece of history without the need for a firearms licence. They are often used for display, film and theatre productions, and historical reenactments. In the UK, for example, deactivated guns must meet the requirements set out by the Home Office and conform to EU regulations. This includes specific standards that vary depending on the type of firearm, ensuring that they are safe and cannot be reactivated.

When it comes to purchasing a wedding band made from a decommissioned gun, it is important to buy from a reputable dealer who can provide documentation of the deactivation process. This ensures that the gun has been properly altered and is in compliance with all relevant laws and regulations. Collectors should also look for proof marks, serial numbers, and other markings that indicate the gun's authenticity and history.

The process of making a wedding band from a decommissioned gun typically involves taking the metal from the barrel of the gun and crafting it into a ring. This metal is strong and durable, making it ideal for jewellery that will last a lifetime. The unique markings and history of the gun can also add a special touch to the wedding band, making it a one-of-a-kind piece.

Overall, shotgun barrel wedding bands made from decommissioned guns offer a unique and creative way to celebrate a couple's love. By choosing a ring made from a deactivated gun, individuals can own a piece of history while also adhering to legal requirements and ensuring their safety.

The Left Hand's Wedding Band Symbolism

You may want to see also

The barrel bands are handcrafted in the USA

Unlike mass-manufactured wedding bands, which are often produced overseas, these barrel bands are crafted in small workshops, with a focus on quality and individuality. The steel shotgun barrel is carefully cut and shaped to form the base of the ring, with some designs featuring a solid gold insert. This combination of recycled steel and precious metals creates a modern ring with a delightful twist.

The handcrafted nature of these rings ensures that each piece is unique. The production time for each order reflects this, typically taking 5-7 business days to create. This attention to detail and quality craftsmanship is a hallmark of these made-to-order rings.

The USA is known for its talented independent designers, artists, and makers, and these barrel bands are a testament to that creative spirit. By choosing to support local artisans, you are not only getting a beautifully crafted ring but also contributing to the preservation of traditional skills and techniques.

These handcrafted barrel bands offer a unique and affordable alternative to traditional wedding bands. With custom orders available, these rings are perfect for those seeking a personalised and meaningful symbol of their love. So, whether you're a fan of the outdoors or simply looking for something different, these made-in-the-USA barrel bands are a perfect choice.

Inexpensive Wedding Bands: Etsy's Secrets

You may want to see also

The ring is cut directly from a steel shotgun barrel

The process of creating these shotgun barrel wedding bands is intricate and precise. It begins with decommissioned gun barrels, ensuring that no working shotguns are harmed in the making of these rings. The barrels are carefully selected and then machine-cut to create the initial band shape. The attention to detail is crucial, as the integrity of the shotgun barrel must be maintained during this process.

Experienced jewellers then take over, skillfully cutting the band to the proper finger size. This hands-on approach ensures a precise fit for the wearer. The next step involves adding a 14kt gold insert, which is secured with a "tack-weld." This combination of steel and gold creates a unique visual contrast.

The ring then undergoes an extensive polishing process, with over six different stages, to achieve a smooth and lustrous finish. Finally, the ring is meticulously inspected to guarantee the highest quality. This entire procedure, from design to completion, took over 18 months to perfect, showcasing the dedication to craftsmanship.

The result is a wedding band that is truly one-of-a-kind, rugged, and symbolic of the wearer's passions. It serves as a reminder that love can be found in unexpected places and that the wild and untamed aspects of life can coexist with the commitments we make to our loved ones.

Wedding Bands: How Much to Put Down?

You may want to see also

The ring is then cut again by hand to the proper finger size

The process of creating a wedding band from a shotgun barrel is a complex and delicate procedure. After the initial design process, which can take months and involve numerous prototypes, the ring is cut directly from a steel shotgun barrel by machine to ensure quality and precision. This stage is crucial, as it lays the foundation for the rest of the process. The next step is just as important: the ring is then cut again, but this time by hand, to achieve the proper finger size.

This hand-cutting stage requires the expertise and precision of experienced jewellers. With their skilled hands and sharp tools, they carefully shape the ring, ensuring that it will fit the wearer's finger comfortably and securely. It is a meticulous process that demands a steady hand and a keen eye for detail. The jewellers must consider not only the size of the ring but also its overall comfort and aesthetics.

The hand-cutting process is a unique blend of art and science, where the jewellers must balance the structural integrity of the ring with the desired finger size. It is a challenging task, as the ring must be strong enough to withstand everyday wear and tear while also being comfortable and elegant. This balance is achieved through precise measurements and careful craftsmanship.

Once the ring has been expertly cut to size, the next step is to add the finishing touches. A 14-carat gold insert is placed inside the ring, enhancing its visual appeal and providing a secure fit. This insert is then securely welded in place, ensuring that the ring remains intact and comfortable for the wearer.

The final stages of the process involve polishing and inspecting the ring. The ring undergoes multiple polishing stages to achieve a smooth, lustrous finish. Each polish refines the surface of the ring, removing any imperfections and enhancing its shine. Finally, the ring is thoroughly inspected to ensure that it meets the highest standards of quality and craftsmanship.

Concrete Wedding Bands: Durable Style?

You may want to see also

The ring goes through several polish stages before reaching its final state

The first rule of polishing is to prepare the surface well and take your time. Any deep marks, scratches, and fire stains may surface during the polishing process, which is frustrating, so it's important to get this part right. The more time and effort put into this stage, the better the results will be. The secret to a high shine is all in the pre-polish.

After construction, the ring will have been through a lot – firescale, pickle residue, large scratches, and the dreaded fire stain. To remove these and make the polishing stage much easier and more effective, you can use graded wet and dry sanding sheets. These have been developed for use with metals and are graded with ultra-fine precision to ensure the best results. The sheets are made from flexible paper, which can be used as they are, or you can wrap a small piece around a block of wood or a similar item to provide a hard backing for quicker sanding results and to prolong the life of the paper.

Another alternative to wet and dry sanding sheets is to use sanding and polishing sticks, which consist of sanding and polishing paper in a variety of grades already secured to flat pieces of wood. Start with the coarsest grade and work all around the ring until every surface is sanded and smooth, then work through all the grades from coarse to fine in the same way. Try to work over the whole ring and move the sanding material and the ring to avoid any flattened areas.

Now is the time to take a critical view of the ring and make sure there are no deep marks or scratches. A headband magnifier can be a useful tool at this stage, as scratches that are not visible to the naked eye can be seen with magnification.

If you find the process of sanding and polishing laborious and are looking for a quicker, easier method, silicon carbide polishing points and wheels may be for you. They provide a fast, neat, and effective way to finish metals and can completely eliminate the need for sanding and greatly reduce the need for filing. They are made from flexible silicon material impregnated with fast-cutting carbide abrasives and come in three different shapes: cylinder, wheel, and knife edge wheel. As with all graded sanding and polishing products, it is recommended to work down through all the grades, starting with coarse and ending with extra fine for the best results.

Hand polishing with polishing papers is another option. After filing and sanding, work your way through the colour grades of the polishing papers, starting with the coarsest and ending with the finest, ensuring that you change the direction of your polishing action between grades for more even results.

Using tripoli and rouge polishing compounds is one of the most widely used methods for polishing. These compounds have minuscule abrasive particles held together in a binder for easy application. Start with tripoli pre-polish and apply the compound to your polishing mop, then start the mop spinning and hold your polish bar against it until you can see the polish on the mop. Firmly grip the ring and gently use the spinning mop all over the piece until it is all pre-polished. Next, follow the same process using rouge, and watch your beautiful mirror finish appear.

Burnishing is another technique that can be used. This involves rubbing hard materials such as steel against softer metals such as silver and gold to smooth rough metal particles down, leaving a shiny surface. Oil or wax can be used to make the action even smoother.

Finally, a barrelling machine can be used to polish multiple pieces or pieces that are hard to polish using a mop. These machines consist of a barrel-shaped container that sits on top of a motor and is rotated. Steel shot is placed inside the barrel with water and barrelling solution, and then the jewellery pieces are placed inside. The machine is turned on for approximately 1-2 hours, and the action of the steel shot gently burnishes the jewellery.

Active Men's Guide to Wedding Bands

You may want to see also

Frequently asked questions

A shotgun barrel wedding band is a ring made from a shotgun barrel.

Shotgun barrel wedding bands are made from stainless steel shotgun barrels.

Each band is machine-cut directly from the shotgun barrel to ensure quality and precision. The band is then cut again by hand to the proper finger size. A 14-karat gold, white gold, or platinum silver insert is then added and secured with a "tack-weld". The band then goes through several polish stages and a thorough inspection.

Shotgun barrel wedding bands are sold by the Florida-based company Everyday Outdoors.